alumina ceramic parts of EV Cars

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | ISO9001, IATF16949, ISO14001, ISO45001, RoHS |

| Model Number: | FS705 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3000 Pieces |

|---|---|

| Price: | USD 0.5~2.5/piece |

| Packaging Details: | Foam+Carton |

| Delivery Time: | 20 work days |

| Payment Terms: | D/P, T/T, Western Union, D/A, L/C, MoneyGram, MoneyGram |

| Supply Ability: | 500,000 pieces per month |

|

Detail Information |

|||

| Material: | Alumina | Color: | White |

|---|---|---|---|

| Application: | Fusegear, Fuse, Electric Protection System | ||

| Highlight: | Heat Resistance Alumina Ceramic Case,95% Alumina Ceramic Case |

||

Product Description

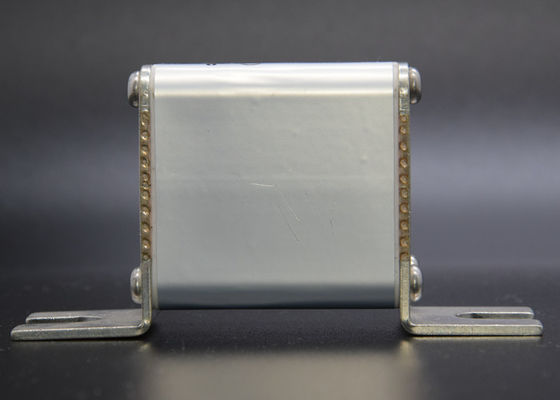

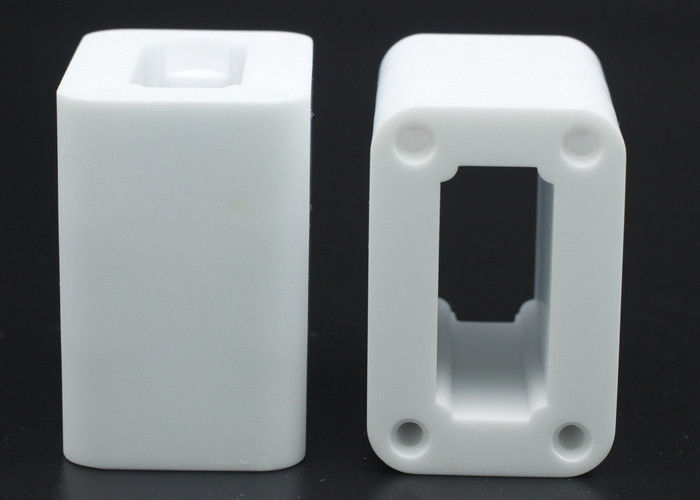

Machining Ceramic Parts for Fuse, 95% Alumina White Porcelain Housing for Fusegear and Electric Protection System

1. Description:

Fuse gear ceramic parts of EV Cars is produced by using high-purity composite alumina combined with dry-pressing method, which are widely used in electrical protection products.

2. Key Words:

Fuse Ceramic, Fusegear ceramic, Electric protection system, New energy, fast-acting fuse, Steatite,uniform texture and good batch stability,

Outstanding arc extinguish competency,high flexural strength, high tensile strength and good air tightness,high frequency, high power and good safety components.charging , new energy vehicles, intercity commuting trains, network equipments.

3. Paremeters shows :

| Product Parameters | ||

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing | |

| Product Dimension | Per customers' drawing | |

| Density (g/cm3) | 3.70-3.75g/cm3 | |

| Water Absorption | 0% | |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa | |

| Hardness (Gpa) | 12.9Gpa | |

| Poisson Ratio | 0.23 | |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 | |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 | |

| Insulation Strength (x106V/M) | 15 | |

![]()

![]()

![]()

![]()