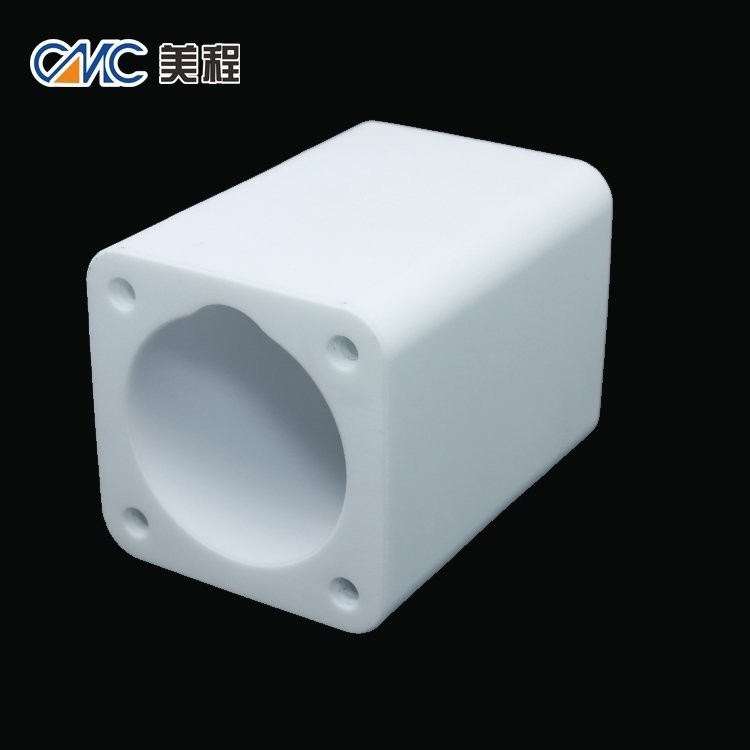

Customized High Hardness White Alumina Ceramic Parts

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | ISO9001, IATF16949, ISO14001, ISO45001, RoHS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2000 pcs |

|---|---|

| Price: | Negotiatial |

| Packaging Details: | Box/Carton |

| Delivery Time: | 20 work day |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80,000/month |

|

Detail Information |

|||

| Density: | 3.8-3.9g/cm3 | Thermal Conductivity: | Low |

|---|---|---|---|

| Hardness: | High | Material: | Alumina Ceramic |

| Dielectric Constant: | 9.6 | Dielectric Strength: | 20kV/mm |

| Wear Resistance: | High | Chemical Resistance: | High |

| Highlight: | Customized Alumina Ceramic Parts,High Hardness Alumina Ceramic Parts,White Ceramic Electronic Components |

||

Product Description

Product Description:

Alumina Ceramic Parts are a kind of industrial components made of alumina, a kind of high-grade ceramic material. They are mainly characterized by their customized shape, white color, high heat resistance, and high wear resistance. In addition, they have good batch stability, good air tightness, and uniform texture, making them suitable for various industrial applications.

Alumina ceramic parts are widely used in many industries, such as in automotive, aerospace, electronics, and medical devices. The material is also used for making cutting tools, bearings, and other mechanical parts. The alumina ceramic parts can withstand high temperatures, and also have high wear resistance and long service life.

Alumina ceramic parts are also known for their excellent corrosion and abrasion resistance. This makes them ideal for harsh environments or extreme conditions. In addition, they are lightweight and non-toxic, making them safe to use for many applications. Moreover, they are easy to clean and maintain, further increasing their utility.

Alumina ceramic parts are manufactured with advanced technologies and strict quality control measures. This ensures that each part is of the highest quality and meets the highest industry standards. They are also cost-effective and can be tailored to fit the specific needs of customers. As a result, alumina ceramic parts are an ideal choice for a variety of industrial applications.

Features:

High Temperature Resistance: Alumina ceramic parts are highly resistant to high temperatures and can work effectively even in extreme thermal environments.

Excellent Hardness and Wear Resistance: Alumina ceramics have extraordinary hardness and excellent wear resistance, protecting them from abrasive forces and letting them keep their structural integrity for a long time.

Electrical Insulation: Alumina ceramic parts have excellent electrical insulating properties, making them perfect to be used in electrical and electronic systems where electrical isolation is a must.

Chemical Resistance: Alumina ceramics are strong against many different compounds, acids, and alkalis, securing their performance and durability in corrosive conditions.

Dimensional Stability: Alumina ceramic parts won’t have any changes in shape and size even during challenging circumstances, guaranteeing their reliability and constancy in critical operations.

Low Thermal Conductivity: Alumina ceramics have low thermal conductivity, ideally used for applications requiring thermal insulation and thermal control.

Precision and Tight Tolerance: Alumina ceramic parts can be built precisely and with tight tolerances, ensuring accurate measurements and compatibility with complicated systems.

Biocompatibility: Alumina ceramics are biocompatible materials, suitable for medical and dental purposes,like implants and prosthetics.

Low Friction Coefficient: Alumina ceramic parts have a low friction coefficient, reducing friction and wear during sliding and rotating operations, thus making the process more effective and durable.

Aesthetic Appeal: Alumina ceramics have a beautiful surface with a smooth and polished look, improving the aesthetic value of products in various industries.

Technical Parameters:

| Parameter | Value |

|---|---|

| Density | 3.8-3.9g/cm3 |

| Dielectric Strength | 20kV/mm |

| Heat Resistance | High |

| Color | White |

| Tolerance | ±0.01mm |

| Size | Customized |

| Hardness | High |

| Thermal Conductivity | Low |

| Electrical Insulation | High |

| Shape | Customized |

| Texture | Uniform |

| Tensile Strength | High |

| Flexural Strength | High |

Applications:

Alumina ceramic parts, with their brand name of CMC, are made in China and are certified with ISO9001, IATF16949, ISO14001, ISO45001, RoHS. With a minimum order quantity of 2000 pcs, the price is negotiable. Packaging is done with boxes/cartons and the delivery time is within 20 work days. Payment terms include L/C and/or T/T. The supply ability is 80,000/month. The surface treatment is glazed and the shape and size can be customized. The dielectric strength can reach up to 20kV/mm and the color of the ceramic parts is white.

These alumina ceramic parts are known for their uniformity in texture, high flexural strength, good batch stability, heat resistance and corrosion resistance. This makes them ideal for numerous applications in industries such as electrical, automotive, electronic, aerospace, medical, chemical and more.

Support and Services:

We provide a range of technical support and services for our Alumina Ceramic Parts, including:

- Technical advice and consultation

- Design and engineering assistance

- Production and product support

- Quality assurance

- Product testing and validation

- Warranty and after-sales service

Packing and Shipping:

Alumina ceramic parts are typically packaged in cardboard boxes, bubble wrap, and other protective packaging materials. The parts are then placed in a cardboard box, surrounded by bubble wrap, and secured with tape. The box is then labeled with the product name, quantity, and destination.

The parts are shipped in boxes or pallets depending on the size and quantity of the order. The boxes or pallets are then placed in a corrugated cardboard container for extra protection during transit. The container is then securely sealed and labeled with the product name, quantity, and destination. The container is then shipped via ground, air, or sea freight depending on the customer's requirements.