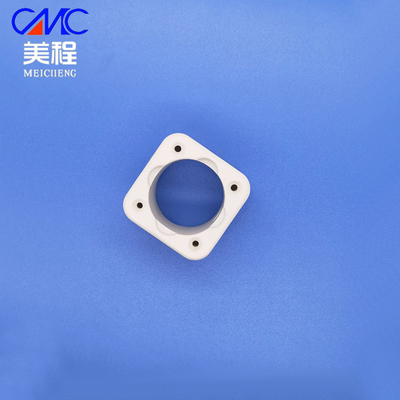

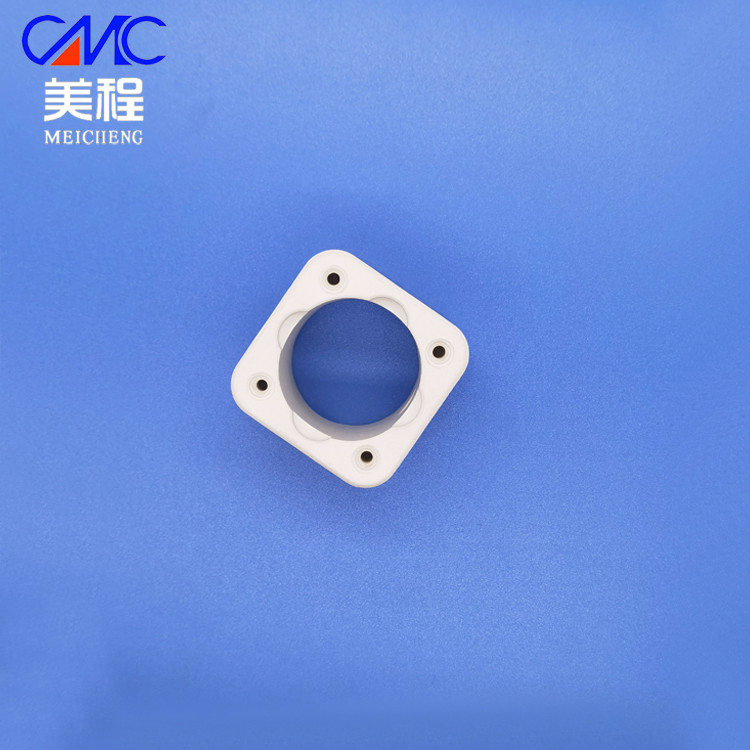

High Electrical Insulation Textured Alumina Ceramic Parts Heat Resistant

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | ISO9001, IATF16949, ISO14001, ISO45001, RoHS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2000 pcs |

|---|---|

| Price: | Negotiatial |

| Packaging Details: | Box/Carton |

| Delivery Time: | 20 work day |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 80,000/month |

|

Detail Information |

|||

| Wear Resistance: | High | Density: | 3.8-3.9g/cm3 |

|---|---|---|---|

| Tolerance: | ±0.01mm | Size: | Customized |

| Color: | White | Electrical Insulation: | High |

| Dielectric Constant: | 9.6 | Hardness: | High |

| Highlight: | Textured Alumina Ceramic Parts,Electrical Insulation Alumina Ceramic Parts,Heat Resistant Ceramic Electronic Components |

||

Product Description

Product Description:

Alumina Ceramic Parts are custom-made parts that possess excellent wear resistance, high electrical insulation, good heat resistance and a tolerance of ±0.01mm. The materials used are of high quality and have good batch stability. As a result, these parts have superior durability and function even under extreme conditions. They can be used for a variety of industries, such as electronics, automotive, aerospace, and medical. Alumina Ceramic Parts are reliable and cost-effective solutions for a range of applications.

Features:

Alumina ceramics possess a wide range of properties that make them an ideal material for a variety of applications.

Firstly, they show exceptional resistance to high temperatures, making them suitable for applications in extreme thermal environments.

Alumina ceramics also possess remarkable hardness and superior wear resistance, allowing them to easily withstand abrasive force.

In addition, alumina ceramics exhibit excellent electrical insulation properties and strong resistance to chemicals, making them suitable for use in electronic and electrical equipment, as well as in corrosive environments.

On top of that, alumina ceramics are also known for their dimensional stability, which allows them to maintain structural integrity even under harsh conditions.

Alumina ceramics also possess low thermal conductivity and high precision machining capabilities, which enable them to be used in applications which require thermal insulation and heat management.

In addition, alumina ceramics are biocompatible materials used in medical and dental applications, such as implants and prosthetics.

Finally, these ceramics feature a low friction coefficient for improved efficiency and durability in sliding or rotating applications, while also offering an attractive aesthetic appeal.

Technical Parameters:

| Property | Value |

|---|---|

| Tolerance | ±0.01mm |

| Dielectric Constant | 9.6 |

| Material | Alumina Ceramic |

| Shape | Customized |

| Electrical Insulation | High |

| Heat Resistance | High |

| Thermal Conductivity | Low |

| Wear Resistance | High |

| Hardness | High |

| Size | Customized |

| Texture | Uniform |

| Batch Stability | Good |

| Flexural Strength | High |

Applications:

CMC's Alumina Ceramic Parts are renowned for their high flexural strength, good air tightness, and good batch stability. They feature an anti-corrosion capability, and have a high temperature resistance and dielectric strength. With a Brand Name of CMC, these Alumina Ceramic Parts are produced in China and have obtained certifications of ISO9001, IATF16949, ISO14001, ISO45001, and RoHS. Each order will require a minimum of 2000 pieces and customers are allowed to negotiate prices. The packaging for these parts can be a box or carton, and the delivery time is estimated to be 20 work days. Payment terms are L/C and T/T, and the supply ability is 80,000 pieces per month. The electrical insulation of these parts is high, and the material used is Alumina Ceramic, which also provides a high wear resistance, and a low thermal conductivity with a dielectric constant of 9.6.

Support and Services:

We provide comprehensive technical support and service for Alumina Ceramic Parts, including:

- Design consultation

- Rapid prototyping

- Manufacturing

- Quality assurance

- Testing and analysis

- Delivery and installation

Our experienced team of engineers and technicians are available to provide advice on the best solution for your Alumina Ceramic Parts needs. We are committed to providing the highest quality products and services, and we strive to exceed your expectations.

Packing and Shipping:

Alumina Ceramic Parts are generally packaged in corrugated boxes with protective cushioning material inside, such as bubble wrap, foam, or shredded paper. The box may also be lined with an inner plastic bag for further protection. In some cases, a wooden box may be used for larger orders. The parts are then secured with tape, and the box is labeled with a description of the product and the customer’s contact information.

Shipping is typically done via ground or air, depending on the customer’s preference. Ground shipping is typically the most cost-effective, but air shipping is often quicker and more reliable. All packages are tracked and insured to ensure they arrive safely and on time.