Dry Processing 95 Alumina Ceramic Sealed Parts IATF16949

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | IATF16949, ISO9001, ISO14001 |

| Model Number: | NE102 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2000 pieces |

|---|---|

| Price: | USD 1.5~3.0/piece |

| Packaging Details: | Plastic film+paper plate+carton |

| Delivery Time: | 20 days |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 60,000 pieces per month |

|

Detail Information |

|||

| Material: | 95% Alumina | Color: | White, Pink |

|---|---|---|---|

| Application: | Relay | Density: | 3.7g/cm3 |

| Highlight: | Alumina Ceramic Sealed Parts,Dry Processing Sealed Parts IATF16949,Dry Processing 95 Alumina Ceramic Parts |

||

Product Description

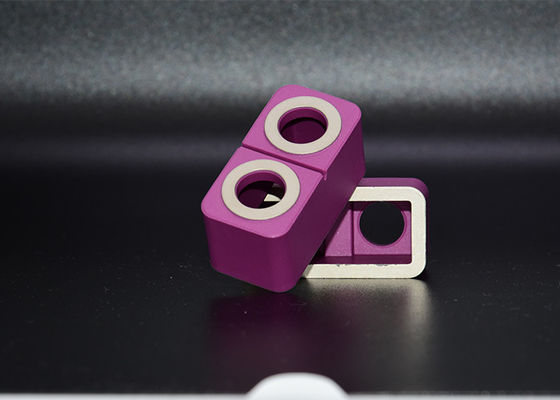

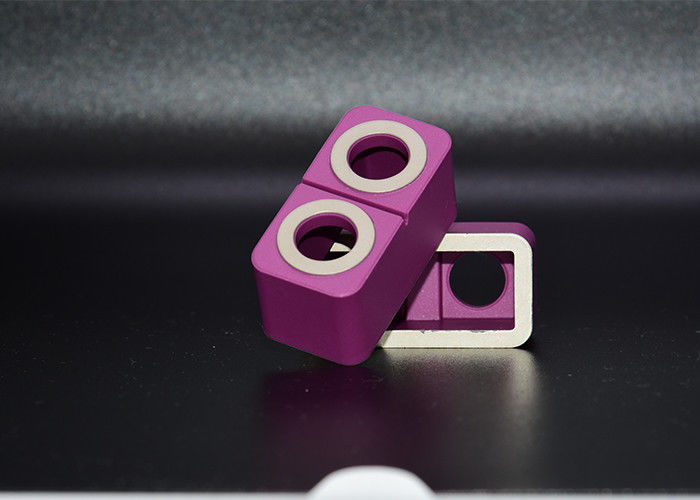

Alumina ceramic sealed parts

1. Description:

Alumina ceramic sealed parts is produced with high-purity toughened alumina ceramics and thick-film nickel plating technology.It is suitable for brazing different materials such as copper and alloys. It can meet the requirements of seismic and tensile at the same time, and it can withstand high current and arc shock. Reaching the reliable sealing and insulation standards of DC high-voltage relays, it is currently an excellent technical solution in the field of new energy vehicles and DC high-voltage electronic control.

2. Applications:

Installing DC relay for new energy vehicle, manufacture samples , open mould ,aluminum oxide,thick-film nickel plating technology,copper and alloys,great limberness,Good corrosion resistance,High intensity,Good high-temperature resistance performance,High purity,95% alumina, dry-processing, customized mold according technical drawing.

3. Parameters:

| Product Parameters | ||

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing | |

| Product Dimension | Per customers' drawing | |

| Density (g/cm3) | 3.70-3.75g/cm3 | |

| Water Absorption | 0% | |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa | |

| Hardness (Gpa) | 12.9Gpa | |

| Poisson Ratio | 0.23 | |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 | |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 | |

| Insulation Strength (x106V/M) | 15 | |

| Metalized Ceramic Performance | Air Tightness (Pa·m3/s) | ≤10-8 |

| Bulk Resistivity (Ω·cm) | ≥1010 (20°C), ≥106 (300°C) | |

| Bonding Strength (Mpa) | ≥120Mpa | |

| Metallization Thickness (μm) | ≥20μm | |

![]()

![]()

![]()

![]()