3.75 G/Cm3 Brazing Advanced Technical Ceramic

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | IATF16949, ISO9001, ISO14001, ISO45001 |

| Model Number: | NE100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2000 pieces |

|---|---|

| Price: | USD 0.2~2.0/piece |

| Packaging Details: | Plastic film+paper plate+carton |

| Delivery Time: | 20 work days |

| Payment Terms: | T/T, Western Union, D/P, D/A, MoneyGram, , MoneyGram |

| Supply Ability: | 60,000 pieces per month |

|

Detail Information |

|||

| Material: | 95% Alumina | Color: | White |

|---|---|---|---|

| Unit: | Piece | ||

| Highlight: | 3.75 G/Cm3 Advanced Technical Ceramic,Brazing Advanced Technical Ceramic,3.75 G/Cm3 Brazing Ceramic |

||

Product Description

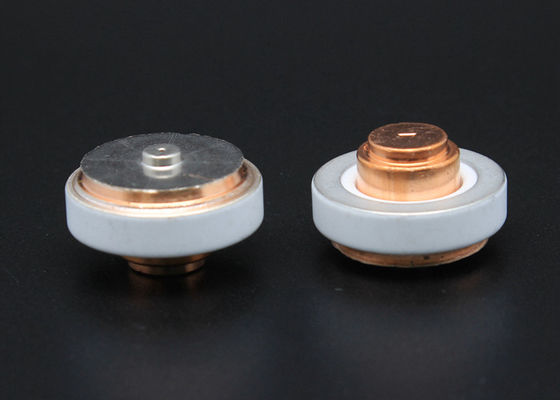

Advanced Technical Ceramic for EV and PHEV Power Battery, 95% Alumina Metallized Porcelain Connector for New Energy Car

1. Description:

The new energy series ceramics are produced by high purity complex alumina and nano metallization. It is suitable for brazing of different materials such as copper, aluminum and kovar. This series consist of HVDC relay ceramic housing, HVDC contactor ceramic shield, Fusegear ceramic case, ceramic connector for power battery cell.

Our products have been designed specifically for new energy applications, including EV cars and PHEV cars. We offer a range of high-quality components, including HVDC contactors, vacuum interrupters, and power battery cell connectors.

Our products are manufactured using ceramics with uniform texture and good batch stability. The nickel layer is compact, continuous, smooth, and provides excellent weldability. The ceramics also offer high flexural strength, high tensile strength, and good air tightness, ensuring exceptional performance in even the most demanding applications.

In addition to their exceptional durability, our products are also designed to deliver high frequency, high power, and maximum safety. They are made from 95% alumina using dry-processing techniques and can be customized in white or other colors based on your needs.

Our products are ideal for use in power charging stations, power storage stations, and urban commuting shuttles. We're dedicated to providing reliable and high-performance solutions for all of your new energy needs. Choose our products with confidence, knowing that they'll deliver the results you need to succeed.

2. Key Words:

New energy, EV Car, PHEV car, HVDC contactor, Vacuum interrupter, Power battery cell connector,uniform texture and good batch stability,compact, continuous, smooth and weldability,high flexural strength, high tensile strength and good air tightness,high frequency, high power and good safety components,95% alumina,dry-processing,white or customized,power charing stations, power storage stations and urban commuting shuttles.

3. Parameters:

| Product Parameters | ||

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing and Brazing | |

| Product Dimension | Per customers' drawing | |

| Density (g/cm3) | 3.70-3.75g/cm3 | |

| Water Absorption | 0% | |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa | |

| Hardness (Gpa) | 12.9Gpa | |

| Poisson Ratio | 0.23 | |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 | |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 | |

| Insulation Strength (x106V/M) | 15 | |

| Metalized Ceramic Performance | Air Tightness (Pa·m3/s) | ≤10-8 |

| Bulk Resistivity (Ω·cm) | ≥1010 (20°C), ≥106 (300°C) | |

| Bonding Strength (Mpa) | ≥120Mpa | |

| Metallization Thickness (μm) | ≥20μm | |

![]()

![]()

![]()

![]()

![]()

![]()