Machining Advanced Technical Ceramics For Fusegear

Product Details:

| Place of Origin: | China |

| Brand Name: | CMC |

| Certification: | ISO9001, IATF16949, ISO14001, ISO45001, RoHS |

| Model Number: | FS705 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 3000 Pieces |

|---|---|

| Price: | USD 0.5~2.5/piece |

| Packaging Details: | Foam+Carton |

| Delivery Time: | 20 work days |

| Payment Terms: | D/P, T/T, Western Union, D/A, L/C, MoneyGram, MoneyGram |

| Supply Ability: | 500,000 pieces per month |

|

Detail Information |

|||

| Material: | Alumina | Color: | White |

|---|---|---|---|

| Application: | Fusegear, Fuse, Electric Protection System | Size: | Size Customized |

| Feature: | High Temperature Resistance,High Wear-resistance | Density: | 3.7g / Cm3 |

| Highlight: | Advanced Technical Ceramics For Fusegear,Machining Advanced Technical Ceramics,RoHS Advanced Technical Ceramics |

||

Product Description

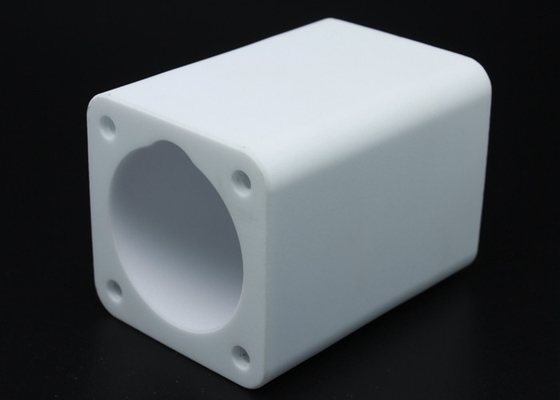

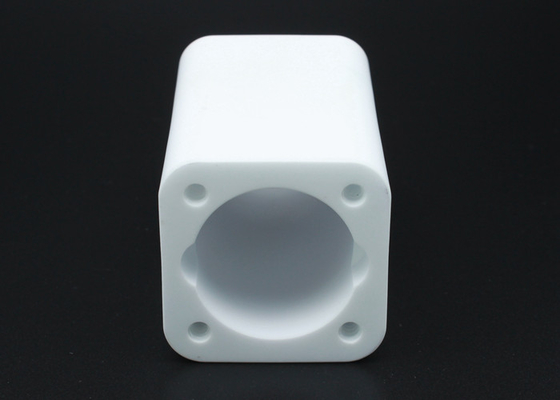

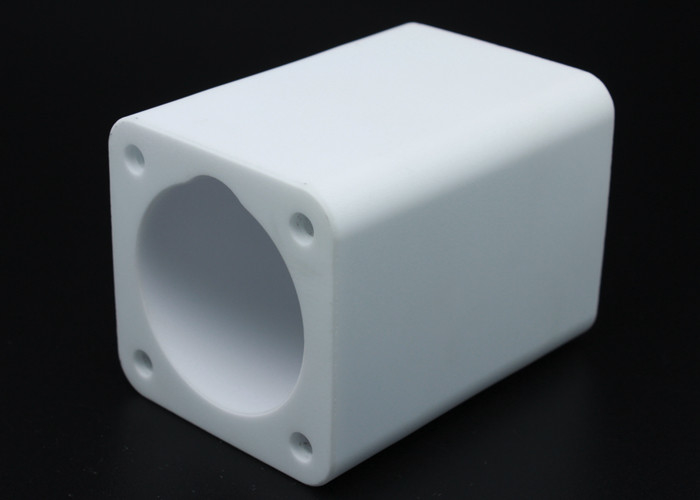

Machining Ceramic Parts for Fuse, 95% Alumina White Porcelain Housing for Fusegear and Electric Protection System

1. Description:

Fusegear series ceramics are produced by using high-purity composite alumina combined with dry-pressing method, which are widely used in electrical protection products.

These ceramic fuses are available in white, beige, pink, or customized colors to suit the aesthetics of any application, and can be used in a variety of settings, including charging stations, power storage stations, new energy vehicles, intercity commuting trains, network equipment, and new infrastructures. Our Ceramic Fuses offer high frequency, high power, and good safety components, making them the ideal solution for your electrical protection needs.

2. Key Words:

Fuse Ceramic, Fusegear ceramic, Electric protection system, New energy, fast-acting fuse, Steatite,uniform texture and good batch stability,Outstanding arc extinguish competency,high flexural strength, high tensile strength and good air tightness,high frequency, high power and good safety components,95% alumina or steatite,dry-processing,white, beige, pink or customized,charging stations, power storage stations, new energy vehicles, intercity commuting trains, network equipments and new infrastructures.

3. Paremeters:

| Product Parameters | ||

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing | |

| Product Dimension | Per customers' drawing | |

| Density (g/cm3) | 3.70-3.75g/cm3 | |

| Water Absorption | 0% | |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa | |

| Hardness (Gpa) | 12.9Gpa | |

| Poisson Ratio | 0.23 | |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 | |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 | |

| Insulation Strength (x106V/M) | 15 | |

![]()

![]()

![]()

![]()